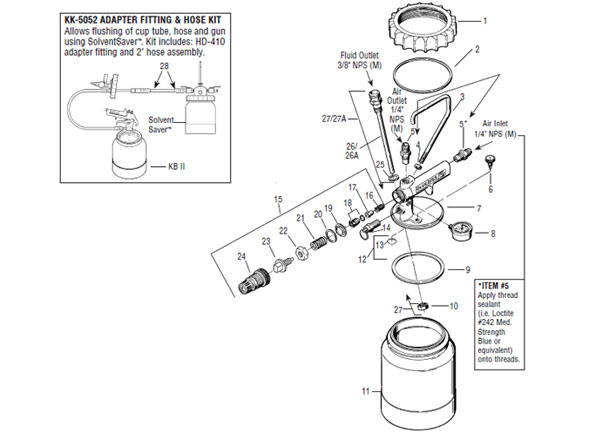

Binks Pressure Pot Setup

Adjust your fluid pressure so that you achieve a light stream flowing from your spray gun do not apply any atomization air yet the stream should be about a 2 3 foot light arcing stream.

Binks pressure pot setup. Pull trigger on spray gun and flow liquid into a measuring cup for 15 seconds. How to properly set up a binks pressure pot and spray gun fluid flow rate. Binks sg 2 plustm pressure cup is ideal for component spraying and industrial applications where small batch production spraying is required. Pressure cup is ideal for compo nent spraying and industrial applications where small batch pro duction spraying is required.

If the pressure on the fluid is more than 20 psi consider a larger fluid nozzle as excess pressure to the spray gun components will cause premature wear of your parts. Connect air to the pressure pot inlet. Before connecting air to the pressure pot make sure all regulators are not turned in at all. Its lightweight and rugged construction is excellent for portability allowing the operator to make fluid and air control adjustments quickly and.

Equipment utilized binks dual regulated pressure pot devilbiss compact trans tech spray gun with 1 4mm fluid needle. Ist regulator is for pot fluid ie. Binks pressure feed containers are used to allow the coating material to be prepared thinned and conditioned constantly agitated if required and then supplied in bulk to consistently maintain the correct spraying viscosity and pressure. Binks sg 2tm plus rotary 2 qt.

Steps to balance a pressure pot click here to download as a pdf set the fluid regulator to 10psi. A good starting point for outbound fluid pressure is 10 lbs. The binks range is equipped with easy to operate air regulators to set the desired fluid outlet pressure safety pressure relief valves and manual rotary or oscillating agitation types are available to provide the best quality agitation. Shut off the atomization air to the spray gun.

Capacity is sufficient to complete large spray jobs without refilling the cup.